加载方式

加载方式

Loading Methods

灵活高效:单一传感器系统可实现动态、热力和真空加载。

Flexible and Efficient: One sensor system for dynamic, thermal and vacuum loading.

动态加载 Dynamic Loading

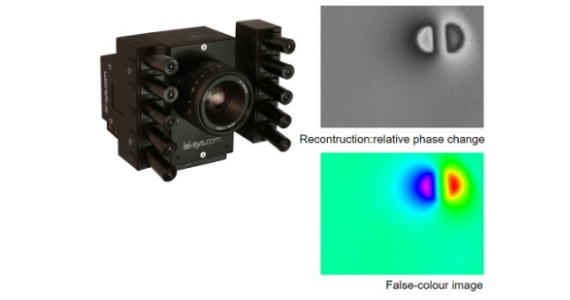

动态加载采用由isi-sys设计的压电振动器激励系统,该系统包含压电振动器、放大器及函数发生器。详细说明请参阅 “Products / Piezoshaker Systems ”。

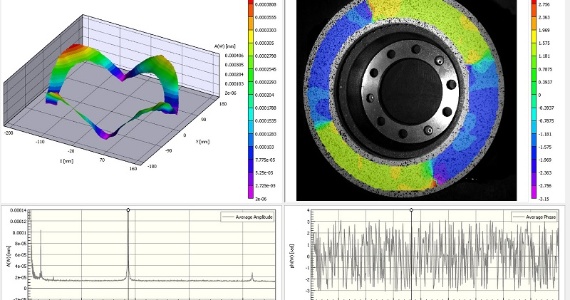

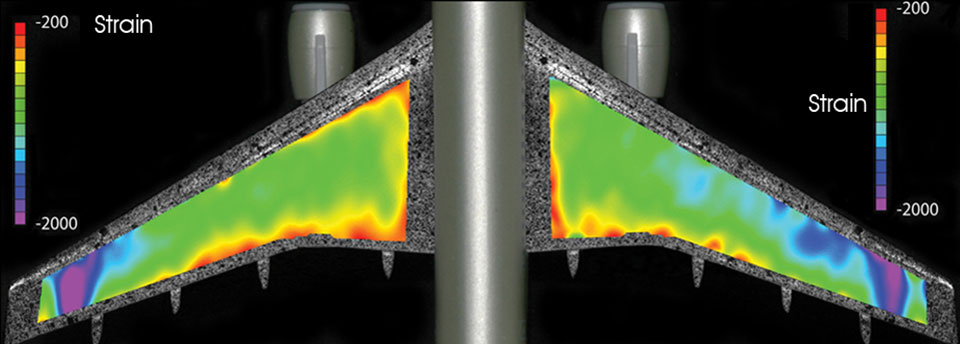

右侧视频展示了安装在试样底部的压电振动器产生的兰姆波。波纹沿物体表面传播,激发顶部五个局部亚表面缺陷。各局部缺陷因其力学特性(刚度)差异产生不同振动。当激励频率接近局部缺陷共振频率时,压电振动器仅需极小功率即可工作。该原理广泛应用于无损检测领域,尤其适用于定位夹层结构中的分层缺陷。

For the dynamic loading the piezoshaker excitation systems are designed by isi-sys. It consists of a Piezoshaker, amplifier and function generator. For a detailed description please refer to the report “Products / Piezoshaker Systems ”

For the dynamic loading the piezoshaker excitation systems are designed by isi-sys. It consists of a Piezoshaker, amplifier and function generator. For a detailed description please refer to the report “Products / Piezoshaker Systems ”

The video on the right shows the lamb waves, generated by the piezoshaker, that is attached at the bottom of the specimen. The waves travel across the object surface and excite the five local subsurface defects on the top. The local defects vibrate differently, depending on their local mechanical properties (stiffness). Only very little power of the piezoshaker is required, when the excitation frequency is close to the local defect resonance frequency. This principle is used in non-destructive testing for example, especially to locate delaminations in sandwich structures.

该压电振动器可通过真空吸附固定于物体表面。HVDA‑0–180放大器专为isi-sys压电振动器及移动应用设计,其轻量化、紧凑型结构与高功率输出特性显著提升了设备机动性与操作灵活性。配合不同型号的isi-sys压电振动器模块,该系统可产生高达100kHz及以上的高频信号,并实现大推力与高加速度输出。

The Piezoshaker can be attached by vacuum to the object surface. The HVDA‑0–180 amplifier is especially design for isi-sys Piezoshakers and mobile application, where high power at low weight and compact size is a big advantage for mobility and flexible handling. High frequencies up to 100kHz and more as well as large forces and acceleration have been generated in combination with the different isi-sys Piezoshaker modules.

热加载 Thermal Loading

isi-sys提供实时热加载模块,用于加热待测物体。

为实现无损检测实验及自动化系统的可重复测试,需对热加载进行自动化精密控制,并配合相应的定时剪切成像测量。

为实现无损检测实验及自动化系统的可重复测试,需对热加载进行自动化精密控制,并配合相应的定时剪切成像测量。

可连接任何常规220V卤素泛光灯。isi-sys推荐使用专业摄影领域的泛光灯具。此类灯具可安装于曼富图等标准灯架,便于独立于传感器头精准照射目标区域,并提供多种反射器组合方案。

热负荷施加与测量的起始时间及持续时长均可通过计算机控制定时器设定,确保测试流程序列的可重复性。

isi-sys offers timed thermal loading modules to to heat-up the objects of measurement.

A automated precise control of heat loading and a corresponding timed shearographic measurement is required to achieve a reproducible test procedure for non destructive testing experiments and automated systems.

Any conventional halogen flood lights with 220V can be connected. isi-sys recommends some flood lights used for professional photography. Thus they can be mounted on standard light stand of e. g. Manfrotto etc. and easily directed to the area of interest independent of the sensor head. Also this lights offer some choices of reflector combinations.

The start and duration of the heat loading and the measurements can be set per computer controlled timer, which permits reproducible sequences of the test process.

真空加载 Vakuum Loading

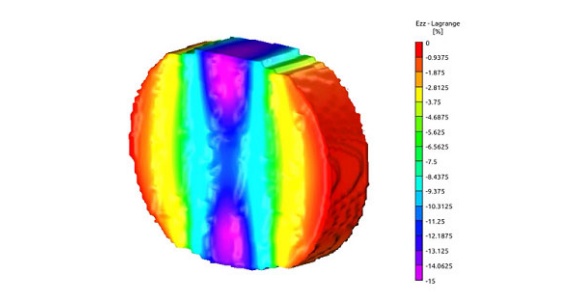

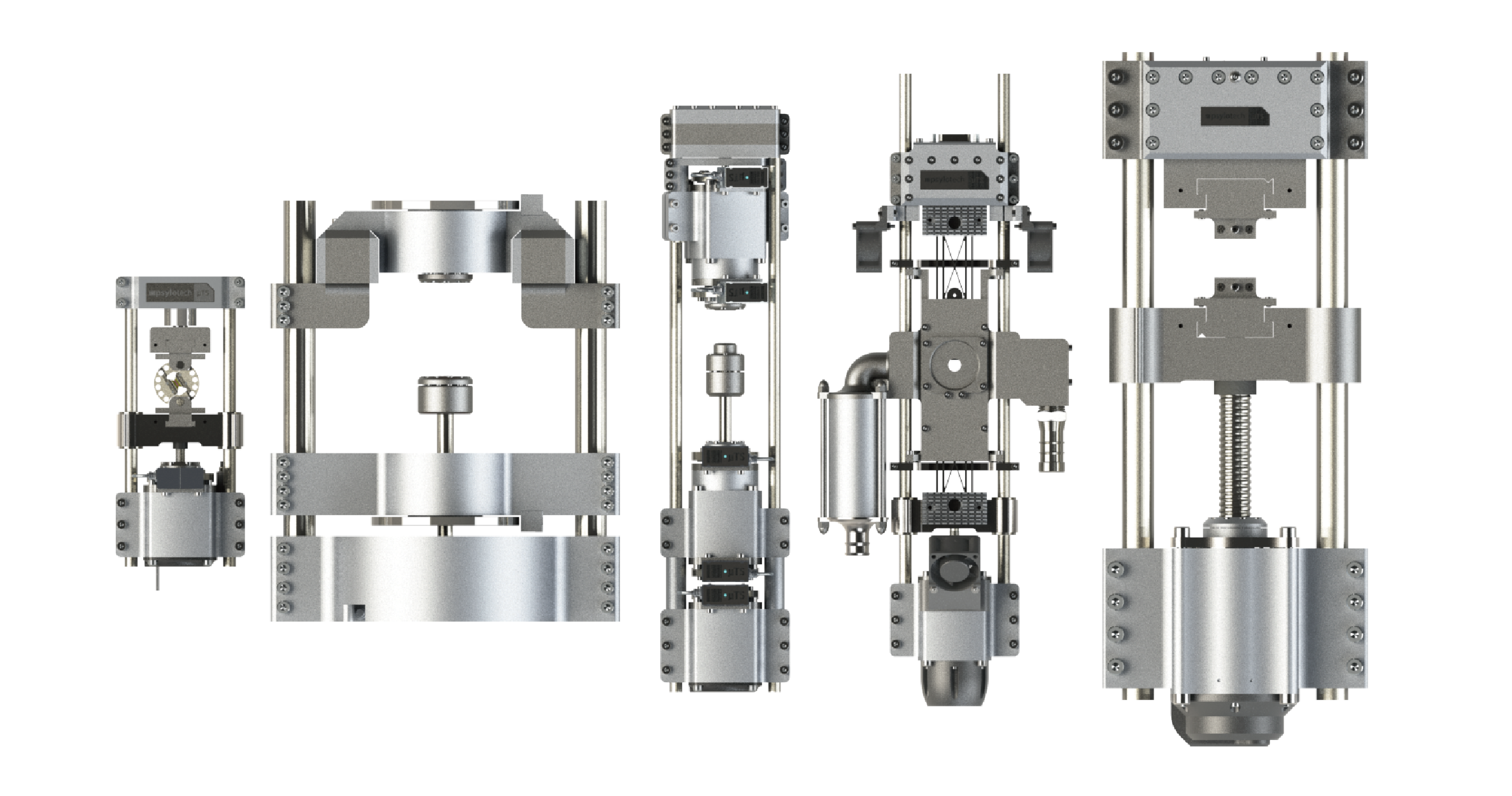

真空是无损检测的另一种加载方式。模块化系统设计理念使SE2传感器能够与不同真空加载装置组合使用,相较于其他解决方案,这既降低了系统成本,又确保设备保持智能与便携特性。

根据加载原理,真空方法可分为真空室/真空舱与真空罩/真空窗口两类。

The vacuum is another loading method for non destructive testing. The modular system concept allows to combine the SE2 sensor with different vacuum loading devices, which reduces system expense and keeps the equipment smart and mobile compared to other solutions .

The vacuum methods can be categorized depending on the loading principle into vacuum chambers/vacuum cabins and vacuum hood/vacuum windows.

真空罩与真空窗口 Vacuum hood and Vacuum window

真空罩是SE2传感器的模块化扩展配件,传感器将安装在罩内,从而使测量区域免受阳光影响。

真空罩是SE2传感器的模块化扩展配件,传感器将安装在罩内,从而使测量区域免受阳光影响。

该系统尺寸紧凑,具有高度移动性和灵活性,所需真空泵功率较低亦。

The vacuum hood is a modular extension accessories for the SE2 sensor. The sensor will be mounted inside of the hood and therfore the measurement area is covered from sun light influences.

The system has small dimensions and is for this reason very mobile and flexible, additionally the low required vacuum pump power is an advantage.

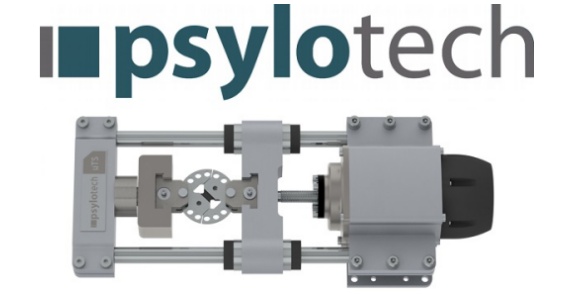

若使用真空窗口,传感器将置于真空腔体之外。系统通过窗口监测物体,弯曲力仅作用于视野范围内。因真空窗口罩体积小巧,可与小型isi真空装置配合使用(该装置亦适用于配备真空吸盘适配器的isi压电振动台)。该装置包含两台独立真空泵,其中第二台可用于真空吸盘三脚架。

若使用真空窗口,传感器将置于真空腔体之外。系统通过窗口监测物体,弯曲力仅作用于视野范围内。因真空窗口罩体积小巧,可与小型isi真空装置配合使用(该装置亦适用于配备真空吸盘适配器的isi压电振动台)。该装置包含两台独立真空泵,其中第二台可用于真空吸盘三脚架。

If you use the vacuum window, the sensor is outside the vacuum volume. The system is monitoring the object through the window. The bending forces are only across the field of view.

Due to the small volume of the vacuum window hood it can be used in combination with the small isi-vacuum unit (also used for isi-piezoshakers with vacuum cup adapter). The unit includes two separate vacuum pumps, where the second can be used for the vacuum suction cup tripod.

真空室与真空舱 Vacuum chamber and Vacuum cabin

相较于真空罩和真空窗,真空室或真空舱通常具有优势,即物体所受力场在各方向上均匀分布。这避免了因整体变形(如真空罩使用时)导致的叠加干涉现象——当真空罩施加于物体表面时,通常仅在单侧表面施加单向压力,从而在物体表面叠加弯曲力。

两种系统中传感器均置于真空腔体内,因此传感器本身也会承受压力载荷。真空室和真空舱体均大于被测物体,故其移动性会因物体尺寸而受限。

isi-sys推出基于铝-泡沫夹层结构的新型测试真空舱,特别适用于高频手动点测或实验室场景。该舱体可测量尺寸达450×750毫米的样品。

此外,isi-sys公司与多家制造商合作提供大型真空室解决方案。

Generally vacuum chambers or cabins have the advantage against vacuum hoods and windows, that the forces appear uniform from all sides on the object. This avoids superposed fringes by global deformation such as by hood, where a bending force on the object surface is superposed, as usually the pressure forces are applied only in one direction on one side of the surface, where the hood is applied.

In both systems the sensor is inside the vacuum volume, which causes pressure loading also on the sensor. The camber and the cabin are bigger than the object and therefore depending on object size the mobility is restricted.

isi-sys offers the newly designed testing vacuum cabin based on aluminium-foam sandwich elements, which is recommended e. g. for frequently manual spot tests or laboratory use. Samples with a size up to 450 x 750 mm can be measured in this cabin.

Furthermore isi-sys GmbH cooperates with different manufacturer for large vacuum chambers.