高速振动分析系统 VIC-3D High-Speed FFT

非接触式全场ODS工作变形与应变测量系统 Non-Contact Full-Field ODS and Strain Measurement System

技术概述 Technology Overview

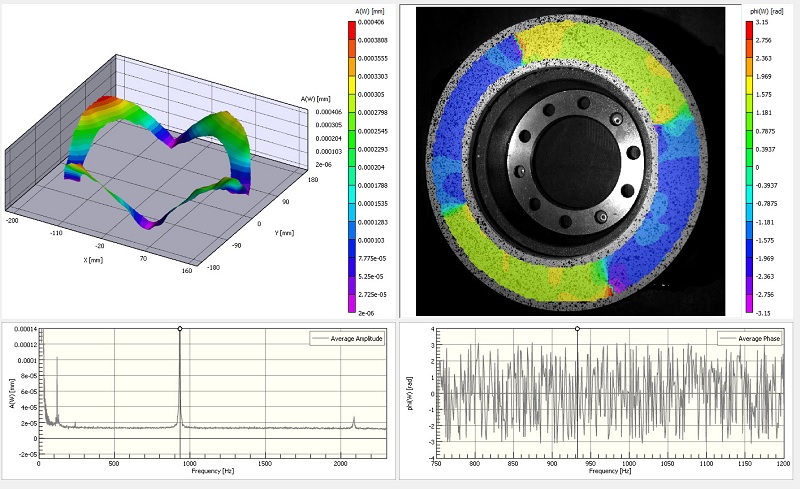

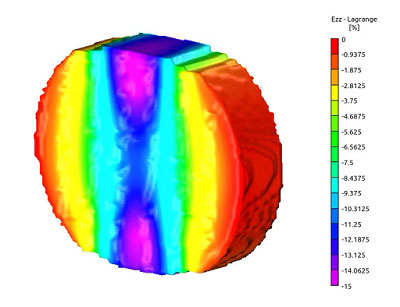

VIC-3D HS FFT 系统是由CSI公司全新增加到 VIC-3D 产品线的测量解决方案, 它能够以全场3D的方式查看、测量和分析在稳态或瞬态事件中的全场工作变形 (ODS) 信息。该系统的纳米级精度易于实现对工作变形 ODS基于频域的查看和分析。系统为测得的任何频率下的3D位移、应变、速度和加速度都提供了数以千计的数据点。其结果不仅是可视的, 而且用户可以导出数据进行有限元分析和验证。

The VIC-3D HS FFT System by Correlated Solutions, Inc. is a new addition to the Vic-3D product line of measurement solutions which enables full-field 3D viewing, measurement, and analysis of full-field operational deflection shapes (ODS’s) which occur from transient events. ODS’s in the frequency domain can easily be viewed and analyzed with levels of accuracy in the nanometer range. Three-dimensional displacements, strains, velocities, and accelerations are all computed for thousands of data points for any given frequency. The result is not only visual, but users can export the data for FEA analysis and validation.

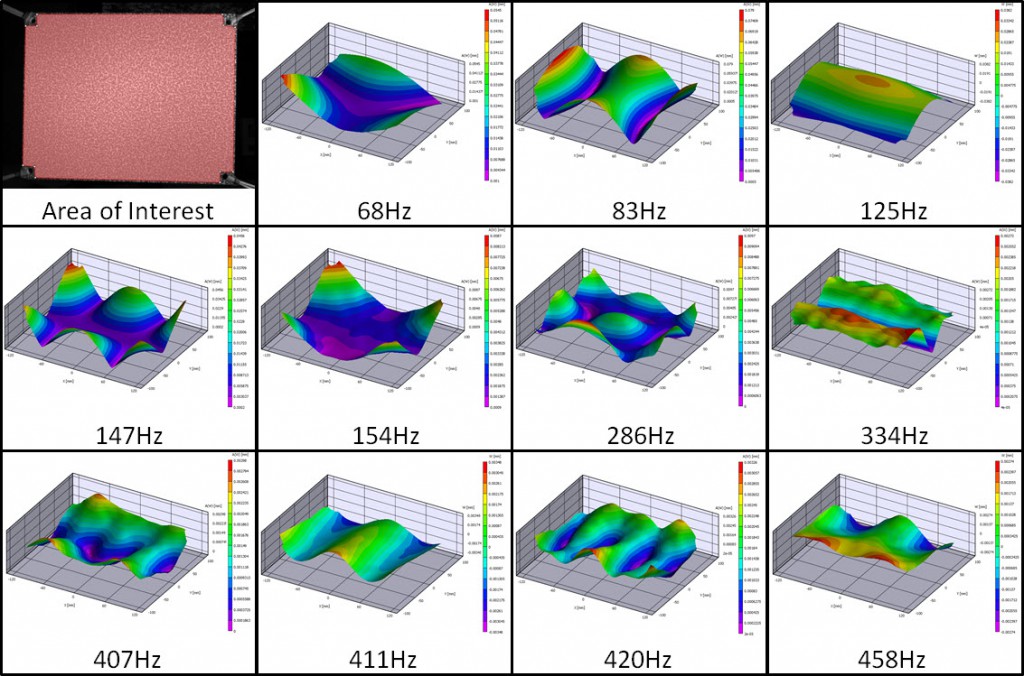

应用案例 Application Example

To see another test, you can check out the brake rotor example on our Applications Page.

与传统测量技术对比 Vs. traditional measurement techniques

- 非接触测量 – 由于 VIC-3D HS FFT 系统提供的是试件在动态或瞬态载荷下的非接触全场振动分析, 该方法避免了传统传感器存在的问题, 比如在实验过程中传感器的脱粘或损坏 (特别是瞬态和冲击加载)、传感器的质量对试件的影响、 以及噪声和电缆管理问题。

- 全场数据 – 完全不需要预先分析选择测量点了!所有点的信息都可以很容易的通过后处理来发现和显示识别。这意味着,不再需要为了确保结果的可靠性,而进行大量的预测试工作。

- 3D数据结果 – 由于 VIC-3D HS FFT 系统始终测量所有X/Y/Z轴的数据, 无需使用大量的单轴加速度计或昂贵的双轴、三轴加速度计。

- 综合应变与位移数据 – 系统自动生成全场应变、变形和振型信息,并伴随所有的频率和振幅数据。

-

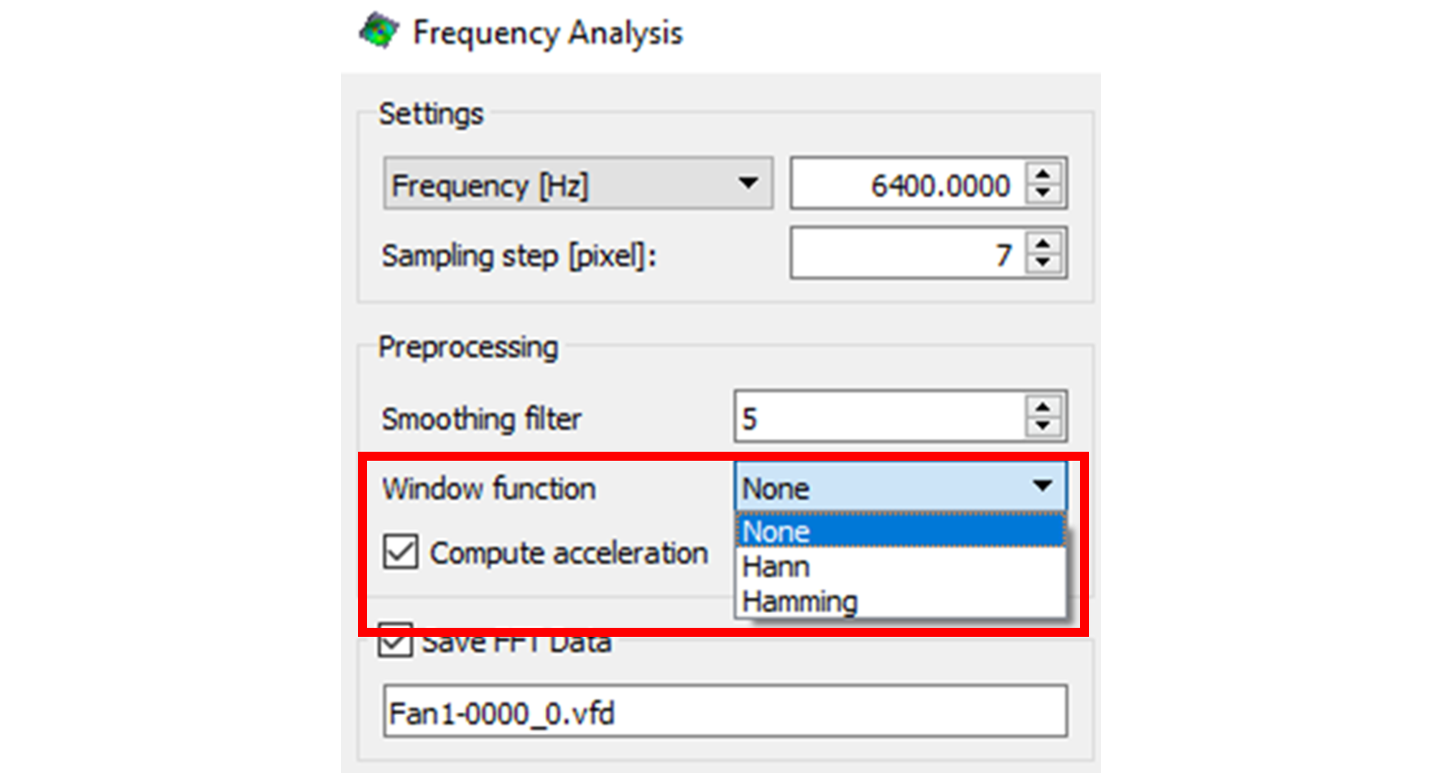

不需窗函数 – 加窗处理被ODS专家描述为该领域的“必要之恶”。通过HSVA系统无需加窗函数,ODS分析人员不用考虑频谱能量泄漏的发生。?(注:数据采集时由于使用矩形窗对信号的时间历程进行截断,从而造成了频谱能量的旁瓣泄漏。使用其他的窗函数就可以改善频谱能量的泄漏,如随机信号使用汉宁、汉明窗,衰减信号使用指数窗等。)

- Non-contact measurements– Since the VIC-3D HS FFT System provides non-contact full-field vibration analysis of components under dynamic or transient load, it circumvents the problems associated with the conventional sensors such as debonding or becoming damaged during the event (especially transient and shock loading), sensors adding mass to the test component, noise, and cable management.

- Full-field data– Point selection can be overlooked completely! Unknown nodes are easily discovered and displayed during post-processing. This means that no pretesting is necessary to ensure reliable results.

- 3D Results– Since the VIC-3D HS FFT system always measures in all three axes, orienting multiple single axis accelerometers or using pricey bi-axial or tri-axial accelerometers are no longer required.

- Integrated strain and displacement data– Full-field strain, deformation, and shape variables are automatically produced along with frequency and amplitude data.

- No Windows– The windowing processing has been described as a “necessary evil” by ODS experts in the field. With the HSVA system, no windows are used, giving the ODS analyst confidence that leakage has not occurred.

使用VIC-3D HS FFT系统,不需要粘合剂、导线、信号分析仪、功率放大器或载荷传感器即可获得详细的ODS结果。 测量微小、复杂的结构或非常大尺度的结构的ODS数据比更换一副镜片更快更容易。

With the VIC-3D HS FFT system, there are no adhesives, wires, signal analyzers, power amplifiers, or load cells necessary for detailed ODS results. Obtaining data for a tiny, complex structure or a very large one is faster and easier than changing a pair of lenses.

新的Vic-3D HS FFT窗函数选项 New Vic-3D HS FFT Windowing Options

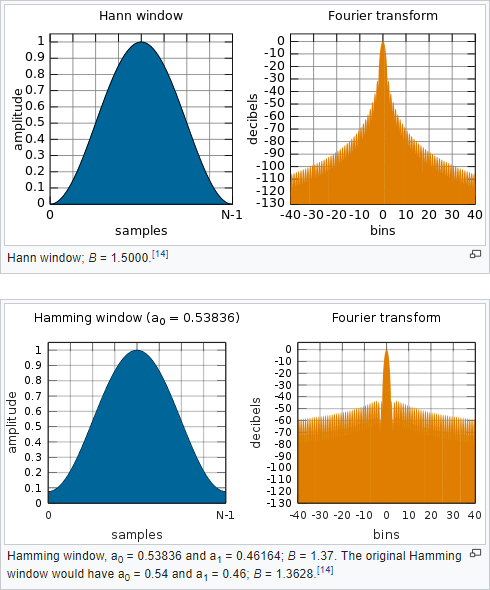

最近CSI公司的软件团队开发并实施了一种对VIC-3D HS FFT系统获得的FFT数据进行后处理的新方法。该方法可以将Hann和Hamming窗口函数应用于FFT数据,以获得更清晰的工作变形ODS信息。这些窗函数功能对于需要更好的频率分辨率但中等旁瓣没有问题的噪声测量很有用。

Recently, our software team has developed and implemented a new way to post-process FFT data obtained with the VIC-3D HS FFT System. The Hann and Hamming window functions can now be applied to the FFT data to produce clearer operational deflection shapes. These window functions are useful for noise measurements where better frequency resolution is wanted but moderate side lobes do not present a problem.

使用窗函数的ODS测量 Operational Deflection Shapes Analyzed with Window Function

VIC-3D HS FFT系统实现了对瞬态事件产生的工作变形(ODS)的全场3D观察、测量和分析。频域中的ODS可以很容易地被观察和分析,其精确度在纳米范围内。可以为任何特定频率下的3D位移、应变、速度和加速度提供数千个数据点的信息。结果不仅是直观可视的,而且可以导出数据为有限元分析和验证。

The VIC-3D HS FFT system by Correlated Solutions enables full-field 3D viewing, measurement, and analysis of full-field operational deflection shapes (ODS) which occur from transient events. ODS in the frequency domain can easily be viewed and analyzed with levels of accuracy in the nanometer range. Three-dimensional displacements, strains, velocities, and accelerations are all computed for thousands of data points for any given frequency. The results are not only visual, but can be exported as data for FEA analysis and validation.

与单点激光测振仪对比 Vs. single point laser vibrometers

- 3D数据结果 – 由于VIC-3D HS FFT系统始终测量X/Y/Z三轴的所有信息,因此测量始终得到的都是3D结果。

- 测量过程简单 - 即使非常大的结构也可以在单个瞬态试验中完成测量。 摄像机不需要移动或重新定位,即可从采样数据中获取更多数据。

- 更快的采集速度 - 使用VIC-3D HS FFT系统,振幅不会影响采集时间。 即使在振幅非常大的超大结构上,全场数据采集时间也只需要几秒钟。

- 综合应变和位移数据 – 全场应变,变形和形状变量随频率和振幅数据一起自动生成。

- 3D Results– Since the VIC-3D HS FFT system always measures in all three axes, 3D results are obtained with each test.

- Simple procedures– Very large structures can be measured in only a single transient test. The cameras do not need to be moved or repositioned at all to acquire additional data from the specimen.

- Faster acquisition– With the VIC-3D HS FFT system, amplitude does not affect acquisition time. Even on very large structures with very large amplitudes, full-field data acquisition time requires only seconds.

- Integrated strain and displacement data– Full-field strain, deformation, and shape variables are automatically produced along with frequency and amplitude data.

VIC-3D HS FFT系统比单点激光振动计具有更强的稳健性和稳定性。 全场3D数据可以非常快速地获取,并且只需很少的设置和测试时间。

Single point laser vibrometers are not as robust as the VIC-3D HS FFT system. Full-field 3D data can be acquired very quickly and with very little setup and testing time.

与扫描式激光测振仪对比 Vs. scanning laser vibrometers

- 更小的设备尺寸 – 用于VIC-3D HS FFT系统的摄像机可安装在单个三脚架上,这使得该系统非常便于携带。 您的3D振动测量系统在实验室间或实验室到现场间的测量转换从未如此简单。

- 更低的经济投入 – 即使是最昂贵的VIC-3D HS FFT系统也只是3D激光扫描振动计系统价格的一小部分。

- 更快的采集速度 – 使用VIC-3D HS FFT系统时,振幅不会影响采集时间。 即使在振幅非常大的超大结构上,全场数据采集时间也只需要几秒钟。

- 综合应变和位移数据 – 全场应变,变形和形状变量随频率和振幅数据一起自动生成。

- Smaller equipment– The cameras used for the VIC-3D HS FFT system fit on a single tripod, which makes the system quite portable. Moving your 3D vibration measurement system from lab to lab or out to the field for testing has never been easier.

- Smaller price– Even the most expensive VIC-3D HS FFT system will be a fraction of the price of a 3D laser scanning vibrometer system.

- Faster acquisition– With the VIC-3D HS FFT system, amplitude does not affect acquisition time. Even on very large structures with very large amplitudes, full-field data acquisition time requires only seconds.

- Integrated strain and displacement data– Full-field strain, deformation, and shape variables are automatically produced along with frequency and amplitude data.

激光扫描测振仪可以提供三维振动测量数据,但体积庞大且非常昂贵。 类比同样的测量应用,使用VIC-3D HS FFT系统,您可以通过更优惠的价格获得更紧凑的设备。

Scanning laser vibrometers provide measurements in 3D, but are quite bulky and very expensive. When compared to acquiring measurements with DIC, you can look forward to more compact equipment at a smaller price.

系统特性 System Features

- 可查看、比较,动画、图形的形式提取和导出数据,便于有限元比较分析

- 3D全场测量,高频率(支持最高50kHz)下纳米级分辨率的工作变形分析

- 极高加速度条件下的极低振幅测量

- 低加速度条件下的极大振幅测量

- 同时提供全场应变,变形和形变量信息

- 简单的测量过程,即可获取高精度的结果

- 用户界面友好

- 投入只需激光测振仪系统价格几分之一

- View, compare, animate, graph, extract, and export data for easy FEA comparison

- Measure 3D full-field, high frequency (50kHz max) operational deflection shapes with nanometer resolution

- Measure extremely low amplitudes with extremely high accelerations

- Measure extremely high amplitudes with low accelerations

- Full-field strain, deformation, and shape variables are still available

- Easy procedures, accurate results

- User friendly interface

- Only a fraction of the price of a laser vibrometer system

VIC-3D HS FFT系统的其他具体应用包括Other practical applications for the VIC-3D HS FFT System include:

- 爆炸试验 Explosive Testing

- 关门试验 Door Slams

- 发动机运转Run-ups/Run-downs

- 冲击试验 Shake Testing

- 跌落试验 Drop Testing