|

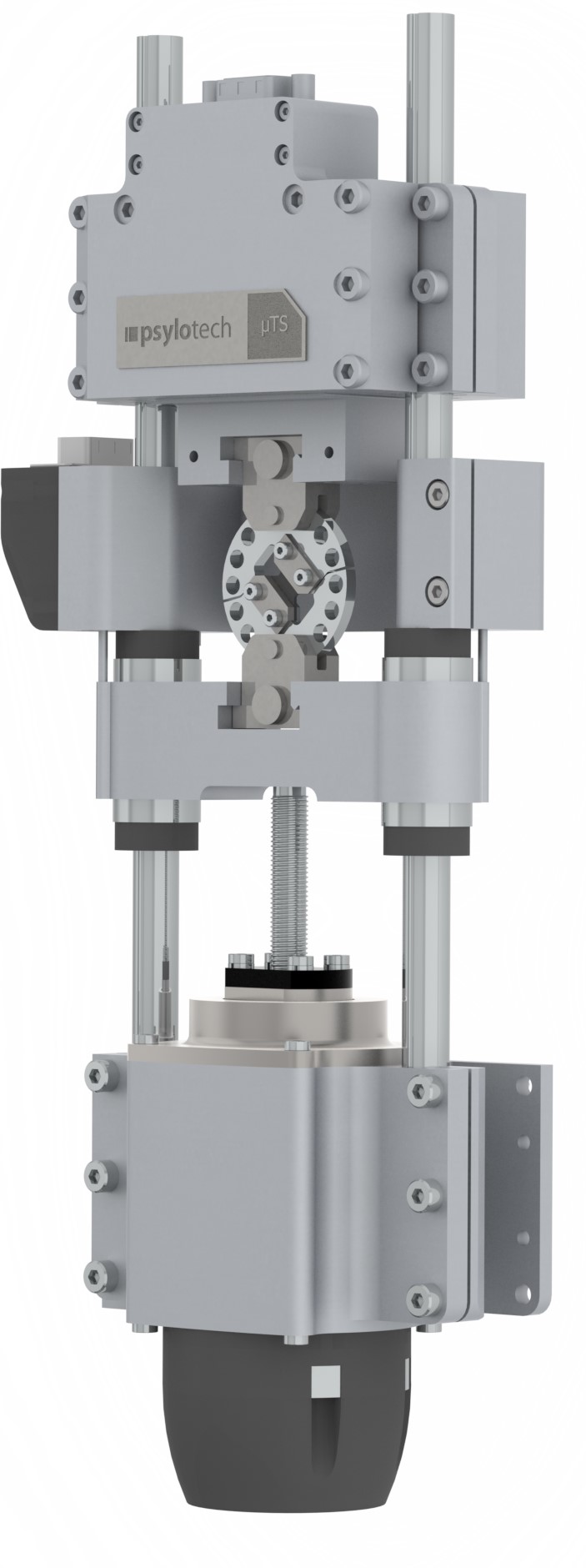

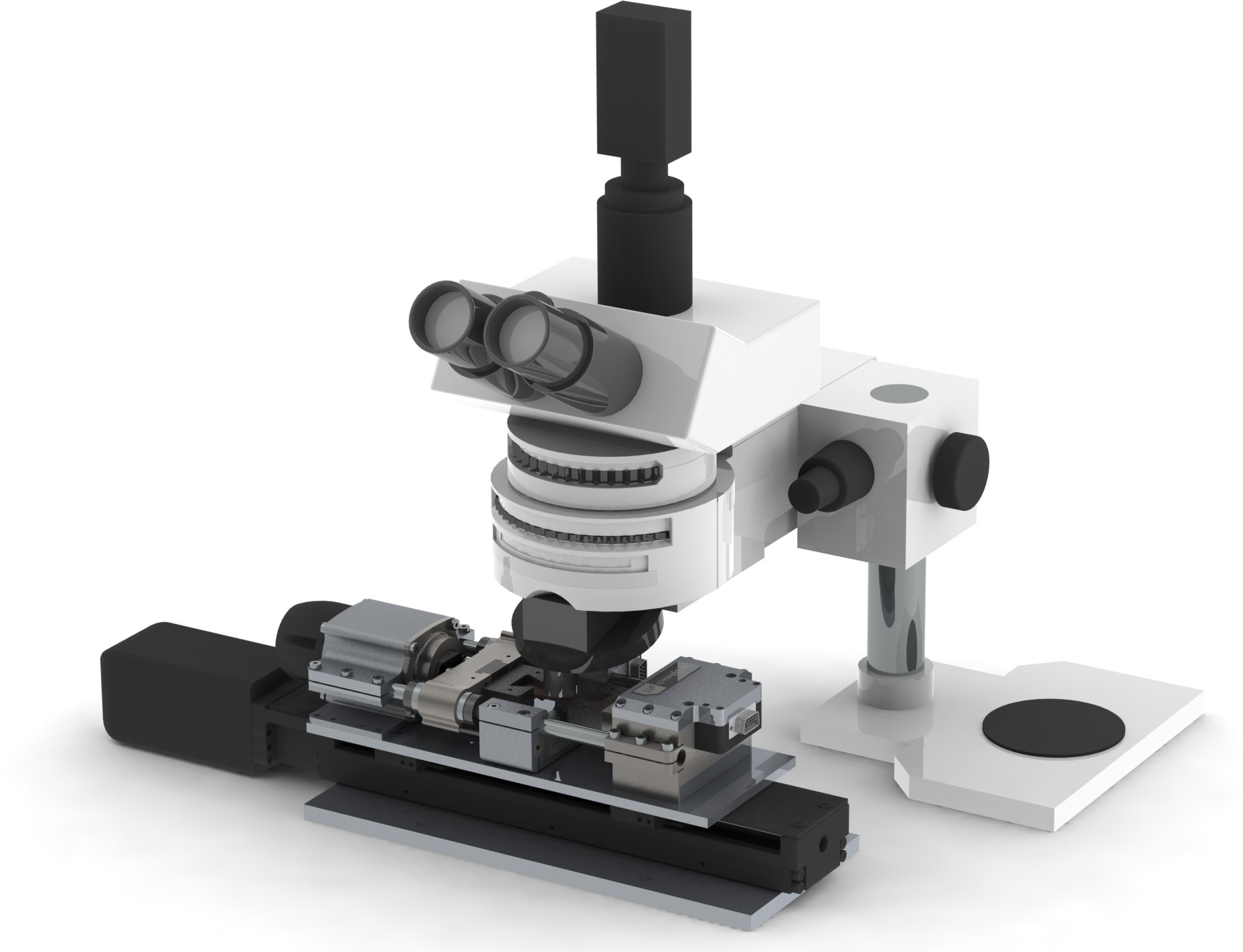

µTS Under-microscope Test System

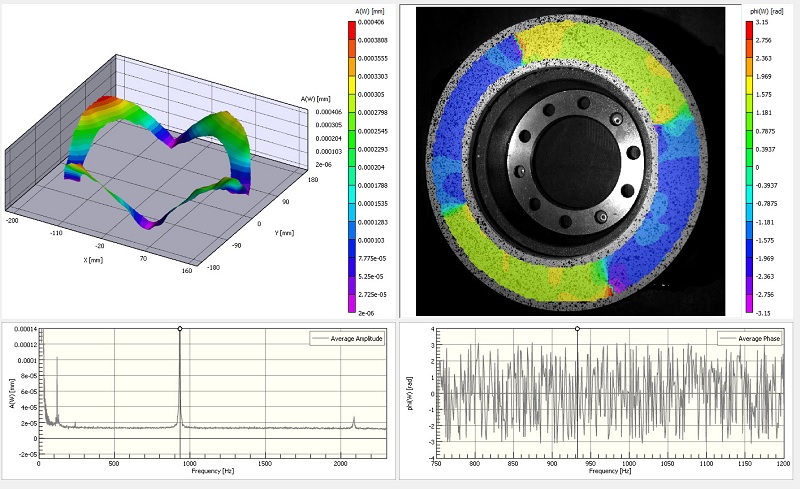

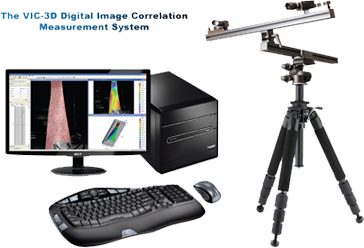

The wavelength of visible light limits optical microscope resolution to 250 nm. Digital Image Correlation (DIC) is a powerful post-processing technique for resolving feature displacements down to 0.1 pixels. Combining DIC and optical microscopes gives 25 nm resolution of the full 2D displacement field. In this way, nano length scale research can be conducted without the need for an AFM or SEM. Moreover, optical microscopy offers the advantage of fast image acquisition.

|

|

• Continuum Model Validation of finite element analysis through multi-scale testing

• Miniature Sample Testing to facilitate material development where quantities can be low

• Unprecedented Versatility to enable implementation of new experimental techniques testing

Continuum Model Validation

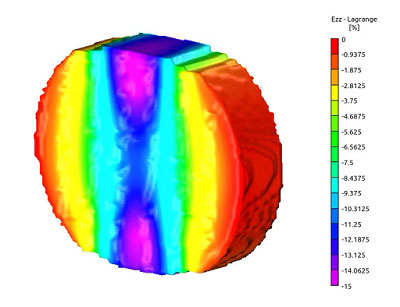

In finite element analysis (FEA), material mechanical properties are presumed uniform to limit the size of elements for reasonable computation times. Psylotech's µTS is a tool to validate continuum models over 6 length scales. Through digital image correlation (DIC) and optimized microscope optics, the full displacement field can be monitored down to 0.1 pixel resolution during a mechanical test. This means up to 25 nm resolution in the displacement field and 0.01% resolution in the strain field, depending on camera resolution.

Consider the example of a composite layup. Typically, FEA presumes uniform, anisotropic material behavior. Tests on a given layup must be experimentally determined in multiple directions. If the layup is modified or the matrix material is changed, new tests should be conducted to re-define material properties. Multi-scale testing offers a vehicle to better understand the interaction between fibers as well as between fibers and the matrix. With test data on smaller scales, continuum properties for any layup can be modeled, skipping an extra experimentation step and accelerating component development time. Moreover, better understanding of small scale interactions and small scale failure mechanisms can lead to fundamentally improved materials.

Miniature Sample Testing

In novel materials research and development, sample yields can be too small to produce full scale ASTM samples. Consider the case of high cost nano-particle reinforced composites. Presuming five specimens are tested to produce statistically relevant data, machined dog-bone samples could prove cost prohibitive. With local strain measurement from the DIC, The µTS can perform accurate tests on significantly smaller samples, offering quality data when less material is available for testing.

Unprecedented Versatility

Psylotech's µTS includes a wide range of features which separate it from any other under-microscope system currently on the market today. These features allow for new possibilities in material testing applications in addition to novel experimental techniques. Some of them include:

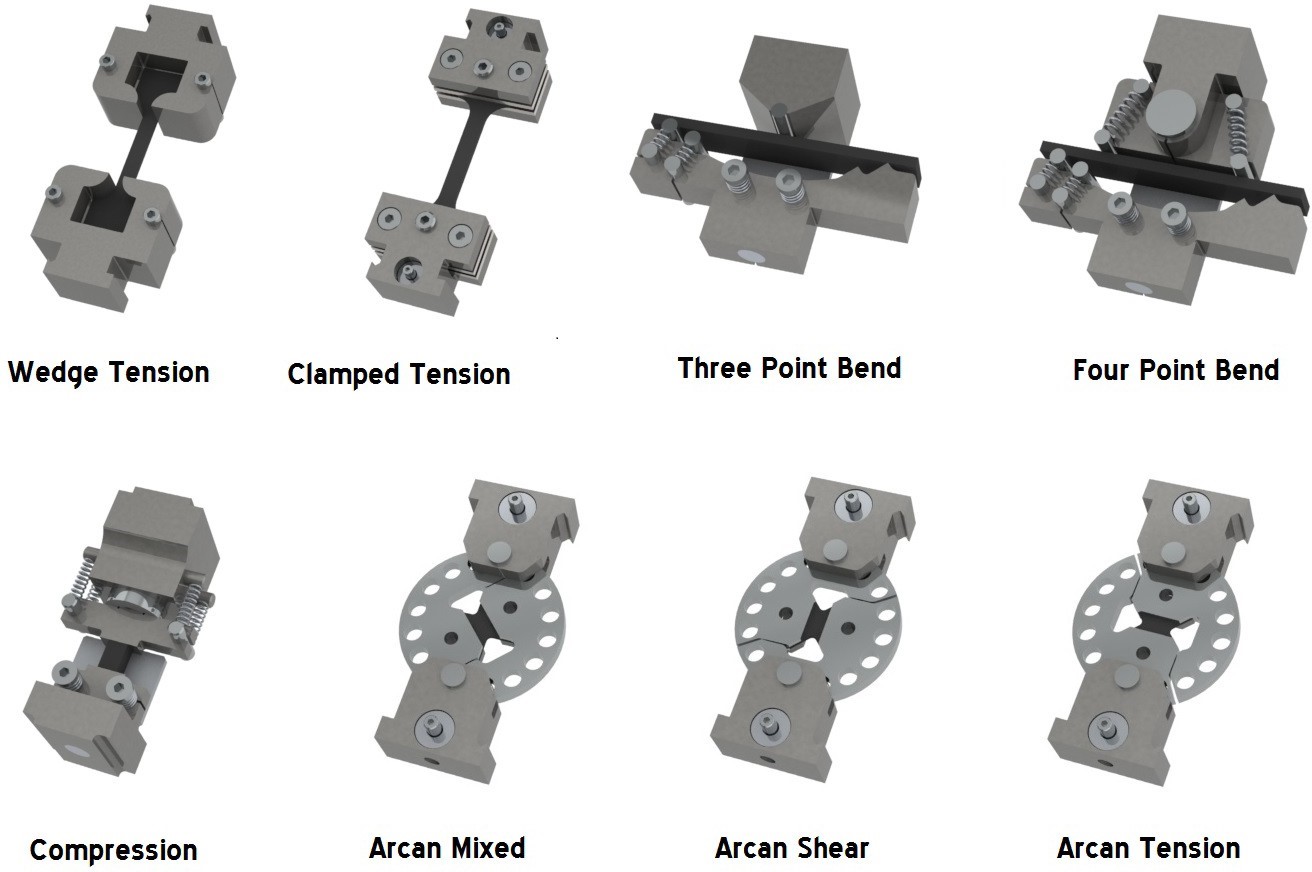

Large Grip Variety

As a versatile universal testing system, the µTS accommodates many mechanical tests. Grip options include: Arcan, tension, film tension, compression and beam bending. These grips also accommodate fracture mechanics testing.

|

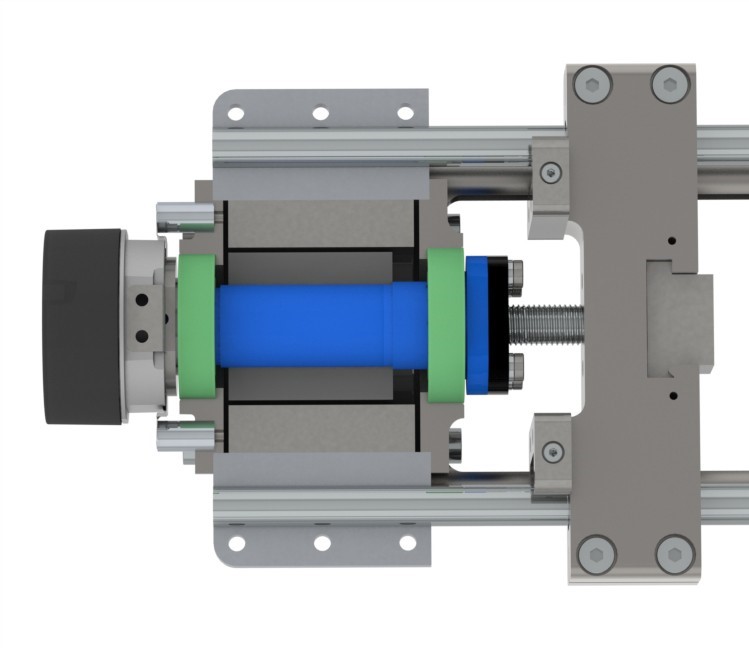

Ball Screw Servo Actuator A low friction, direct drive, ball screw actuator facilitates precision motion control, compared to lead screw actuators and covers 8 orders of magnitude in speed. With peak speed performance approaching a standard servohydraulic universal test frame, the µTS is effective for step-load and load control experiments. The system can also operate in cross-head displacement control or motor drive shaft position control. |

|

|

|

High Resolution Load Cell Psylotech uses a capacitive load cell with 200x higher sensitivity compared to strain gauged sensors. With higher sensitivity and a similar signal to noise ratio, the proprietary sensor technology has 100x higher resolution such that a 1600 N cell can offer sub-mN resolution. High resolution reduces the need to install smaller range load cells for low force tests. Keeping the load cell installed improves lab efficiency, eliminating installation and load train realignment time. |

|

|

|

High Resolution Cross-head Displacement Sensor Psylotech uses an inductive displacement sensor for measuring local strains directly at the cross-head. With a range of 25 mm and resolution of 25 nm, this tool allows for very small, controlled moves as close to the specimen as possible. The support posts on either side of the system can be adjusted depending on the gauge length of the specimen. Custom post lengths available upon request. |

|

|

|

X-Stage Option An available X-Stage option makes it possible to keep the area of interest centered within the field of view of the microscope objective throughout the test. This is achieved via the control software which slaves the X- Stage to the moving cross-head by a user adjustable ratio. The µTS mounts directly on top of the X-Stage, all mounting hardware included. The X-Stage is capable of covering the full primary stage travel. |

|

|

|

LabVIEW Control Software Keeping with the theme of giving experimentalists a tool to develop new techniques, Psylotech offers the user access to the LabVIEW source code, including the closed loop control. Advanced users can make adjustments to suit their specific needs or personal preference. |

|

|

|

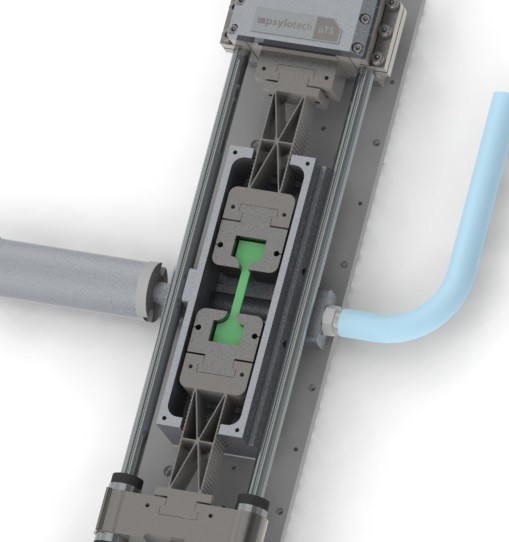

Temperature Chamber Validating thermomechanical models is accelerated with an optical microscope compatible temperature control module. The chamber allows -100C to +200C tests with precise and accurate DIC, load and cross-head displacement measurements. Stability is better than .5C and fast ramp speeds cover the entire temperature range in minutes. Liquid nitrogen hookups are integrated with a high flow rate blower that ensures even temperature distribution around the specimen. |

|

| Specifications | 1.6kN Micro Frame | 10kN Mini Frame |

|---|---|---|

| Force Capacity (N) | 1600 | 10000 |

| Load Resolution (mN) | 0.5 | 3 |

| Stroke (mm) | 40* | 100* |

| Displacement Resolution (nm) | 25 | 25 |

| Minimum Rate (nm/s) | 1 | 5 |

| Maximum Rate (mm/s) | 80 | 140 |

| Peak Acceleration (m/s2) | 10 | 30 |

| Analog Sensor Outputs | BNC | BNC |

| Envelope (mm) | 100 x 54 x 300 | 200 x 123 x 650 |

| Mass (kg) | 1.5 | 23 |

| Control Loop (Hz) | 500 | 500 |

| Power Requirement | 120/240V, 60/50Hz | 120/240V, 60/50Hz |

* Custom force capacities and strokes available upon request.

• The µTS includes the load frame, a set of grips, electronics hub and control computer.

• For optimal results, the µTS package is complemented with a high quality microscope, camera and digital image correlation software (see below)