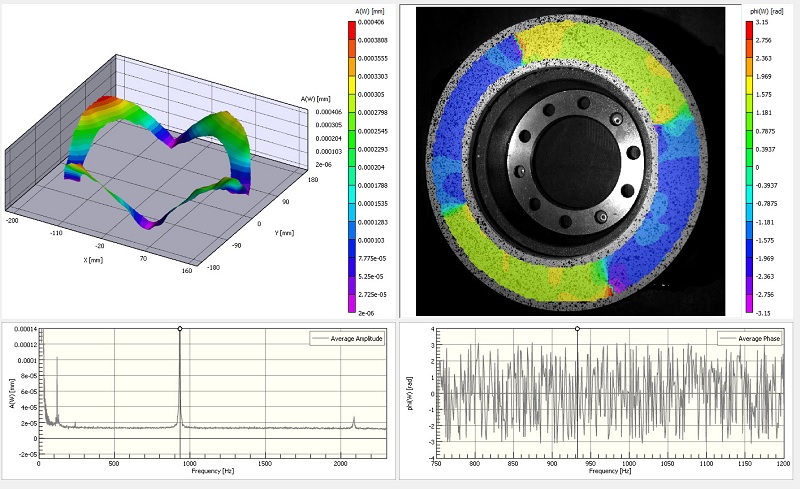

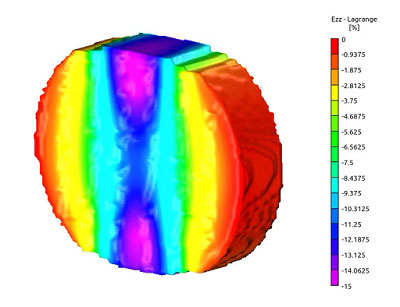

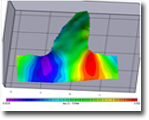

A plastic gear assembly was being evaluated to better understand interactions between component parts. In addition to strain measurements, it was desirable to obtain deflection data in three dimensions.

技术挑战 Challenges

应变测量Strain measurement

应变测量Strain measurement

装配在一起的齿轮工作时通常具有复杂的交互作用。 由于齿轮的转动,轮齿接触点在运行周期中会有不断变化。 这意味着峰值应变的位置很难预测,而且它们通常也不是定值。 齿轮的转动也导致与传统电测应变片保持连接变得不切实际。 即使工件处于静止且易于定位时,应变峰值也可能集中在非常小的区域或具有高应变梯度变化,而应变片产生的平均效应可能会造成峰值结果的损失。

Assembled components typically have complex interactions with one another. Contact points can vary during operational cycles due to part movement. This means that the locations of peak strains can be hard to predict, and they are often not stationary. The movement of parts can also make it impractical to maintain electrical connections with gauges. Even when they are stationary and easy to locate, the highest strains can be concentrated in very small areas or have high gradients. Peak values may be lost to the averaging effect produced by gauges.

解决办法 Solution

位移Displacement

位移Displacement

CSI公司的VIC-3D提供了一种可用于齿轮整个轮廓上进行应变测量的方法。 因为它提供了全场测量,所以没有必要选择特定的点进行测量, 这样可以在运行周期的各个阶段清楚地显示和精确测量峰值应变。 VIC-3D同时提供了三维位移的测量数据。 该功能使我们的客户能够识别和量化负载下轮齿的扭转变形。

Correlated Solutions’ VIC-3D provided a means for making strain measurements across the entire profile of the gear tooth. Because it provides full-field measurements, it was not necessary to choose a particular point at which measurements would be made. This allowed the peak strains to be clearly visualized and accurately measured at various stages of the operational cycle. VIC-3D also measured displacement in three dimensions. This feature allowed our customer to recognize and quantify twisting of the gear tooth under load.

相关链接Links

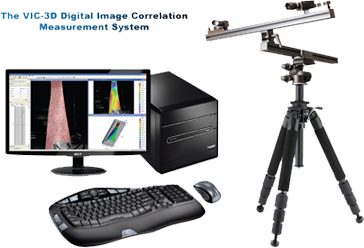

View the VIC-3D system for more information about this technology.