NanotestXtreme 超高温真空纳米力学综合测试系统Xtreme

With the NanoTest Vantage, Micro Materials already offers the most comprehensive range of nano-mechanical test options.These are now further extended with the NanoTest Xtreme, which provides a vacuum environment testing from -100 to 1000 ºC without oxidation or frosting of samples.

借助 NanoTest Vantage,Micro Materials 已经提供了最全面的纳米机械测试选项。NanoTest Xtreme进一步扩展了这些功能,它提供了从-100到1000ºC的真空环境测试,而不会使样品氧化或结霜。

Suitable for investigating the effect of more extreme environments than ever before for:

适用于研究比以往任何时候都更极端的环境对以下方面的影响:

(1)Low oxygen, low temperatures for satellite development 低氧、低温卫星开发

(2)High temperatures for aerospace engine components 航空航天发动机部件的高温

(3)High temperatures for power station steam pipes 电站蒸汽管道高温

(4)Irradiation effects in nuclear reactor cladding 核反应堆包壳中的辐照效应

(5)The effect of cold on weld repairs in oil/gas pipelines 冷对油气管道焊缝修复的影响

(6)Tool coatings for high speed machining 用于高速加工的刀具涂层

Vacuum, high and low temperature capability

真空、高低温能力

1.真空测试

Micro Materials has considerable experience in providing instruments capable of high and low temperature testing. Until recently, the limitations of these have been oxidation at high temperatures and condensation/frosting at sub-zero temperatures. Testing under vacuum negates these and allows further expansion of the temperature capabilities of the NanoTest.

Micro Materials在提供能够进行高温和低温测试的仪器方面拥有丰富的经验。直到最近,这些的局限性一直是高温下的氧化和零下温度下的冷凝/结霜。在真空下测试可以消除这些条件,并允许进一步扩展NanoTest的温度能力。

2.高温可至1000℃

NanoTest Xtreme’s extended high temperature capabilities beyond the 850 °C provided by the NanoTest Vantage,The unique design allowed scientists at RWTH Aachen University in Germany to push testing temperatures up to 1000 °C and gather valuable information on the hardness and creep behaviour of an Amdry-386 bond coat.

NanoTest Xtreme扩展的高温能力超过 NanoTest Vantage 提供的 850 °C,其独特设计使德国RWTH亚琛大学的科学家们能够将测试温度提高到1000°C,并收集了有关Amdry-386粘结涂层的硬度和蠕变行为的宝贵信息。

3.低温至100℃以下

Enhanced low temperature capability to below -100 °C without frosting of samples 将低温能力增强至-100°C以下,不会结霜

Ability to backfill with gas to match material operating environments 能够回填气体以匹配材料操作环境

Experimental cases

实验案例

1.micro-cantilever bending experiments on silicon 硅微悬臂弯曲实验

The NanoTest Xtreme allow scientists to undertake research in areas not accessible using conventional nanoindentation hardware. This makes the Xtreme an invaluable tool in advancing the frontiers of materials research.

NanoTest Xtreme 允许科学家在使用传统纳米压痕硬件无法进入的领域进行研究。这使得 Xtreme 成为推动材料研究前沿的宝贵工具。

Work done using the Xtreme at the University of Oxford focused on extending the fundamental understanding of the behaviour of silicon at elevated temperatures. Micro cantilever bending experiments are used to determine the mechanical properties at different temperatures in order to examine the changing deformation mechanics.

牛津大学使用Xtreme完成的工作重点是扩展对硅在高温下行为的基本理解。微悬臂弯曲实验用于确定不同温度下的力学性能,以检查变形力学的变化。

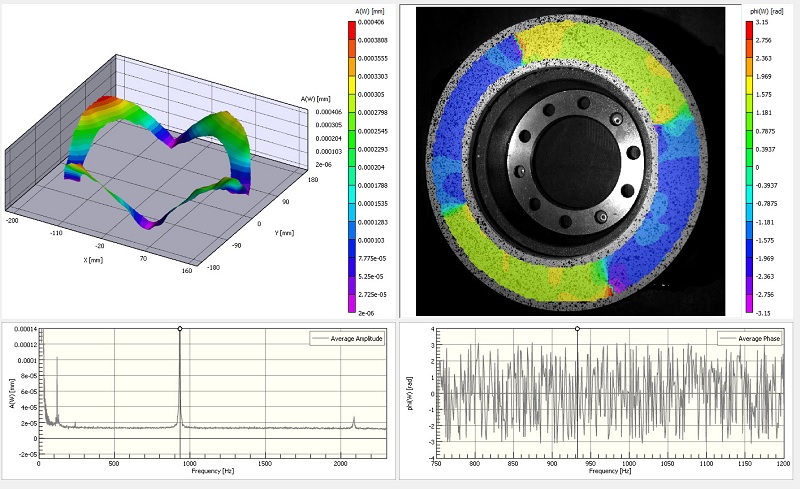

Typical load vs displacement data for bending experiments performed at 110 ºC and 700 ºC are shown in Figure 3. There is a clear difference in the behaviour of the silicon at the two temperatures. The silicon is brittle at 110 °C and ductile at 700 °C.

在110 ºC和700 ºC下进行的弯曲实验的典型载荷与位移数据如图3所示。硅在两种温度下的行为存在明显差异。硅在110°C时易碎,在700°C时具有延展性。

2. high temperature nanoindentation experiments on silicon performed in vacuum 在真空中对硅进行的高温纳米压痕实验

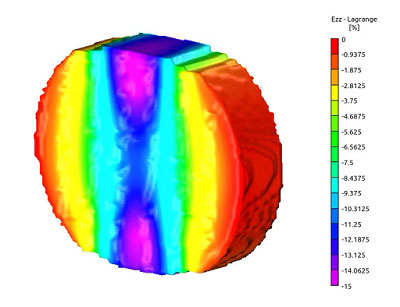

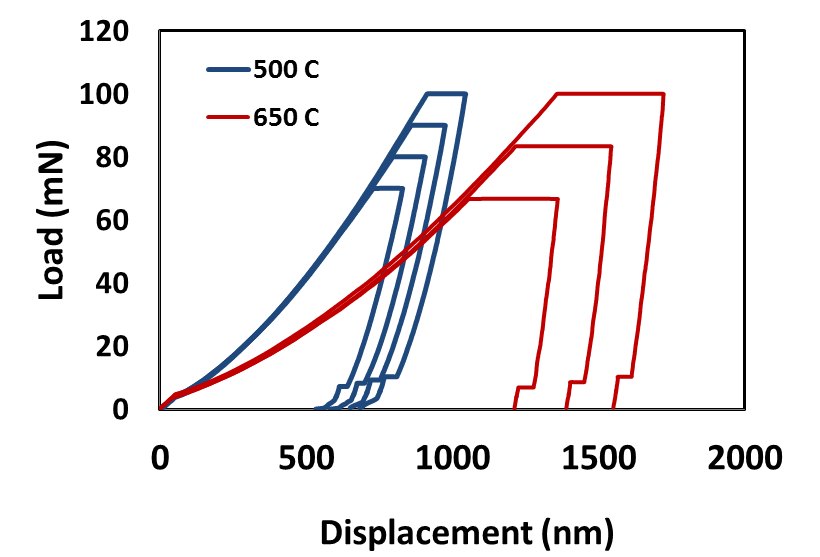

High temperature nanoindentation measurements confirm the temperature at which the silicon’s behaviour transitions from brittle to ductile.The picture shows indentation experiments performed at a variety of loads at 500 ºC and 650 ºC.

高温纳米压痕测量确认了硅的行为从脆性转变为延展性的温度,图中数据显示了在 500 ºC 和 650 ºC 下在各种负载下进行的压痕实验。

The increased creep during the hold at peak load as well as the change in the unloading behaviour both indicate that there is a transition in the material.

在峰值载荷下保持期间蠕变的增加以及卸载行为的变化都表明材料行为在500 ºC以上发生了转变。

Key Features

关键特性

(1)Maximum testing temperature under vacuum for 500 mN loading head:1000°C

500mN加载头真空下的最高测试温度:1000°C

(2)Maximum testing temperature under vacuum for 30 N loading head: 1000 °C

30N加载头真空下的最高测试温度:800°C

(3)Minimum testing temperature under vacuum: -50 °C

真空条件下的最低测试温度:-50°C

(4)Ultimate vacuum: 10-7 mbar 极限真空:10-7毫巴

(5)Compatible with all standard NanoTest techniques under vacuum:(nanoindentation, nano-scratch, nanowear, nano-impact, nano-fretting)

兼容真空下的所有标准纳米测试技术:(纳米压痕、纳米划痕、纳米耳、纳米冲击、纳米摩擦片)

(6)Option of a second loading head increases maximum load from 500 mN to 30 N

选择第二个加载头增加最大负荷:500mN至30N

(7)Backfill function to test in non-air gas environments

回填功能用于非气体环境中测试

(8)High resolution optical microscope 高分辨率光学显微镜

(9)Option to add SPM imaging/nanopositioning stage which can be used over the full temperature range

选项,添加SPM成像/纳米定位阶段,可在全温度范围内使用

Specifications

技术规格