xTS – Mechanical Testing System In X-ray Tomography Imaging System

X射线断层图像系统的原位加载系统

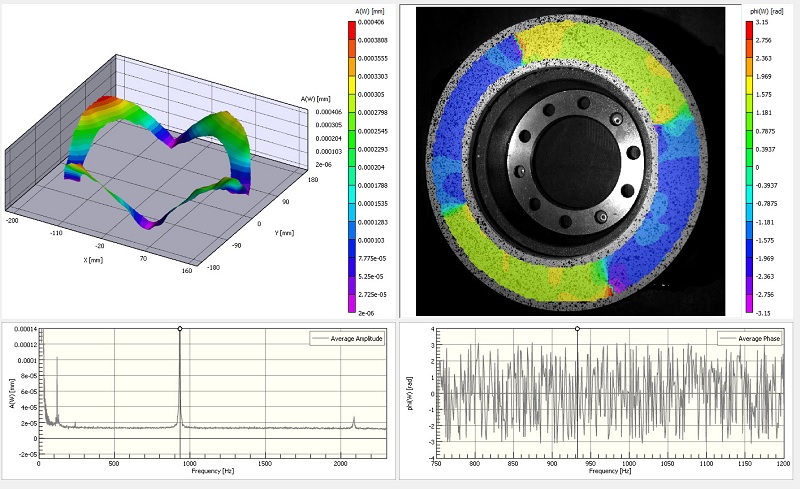

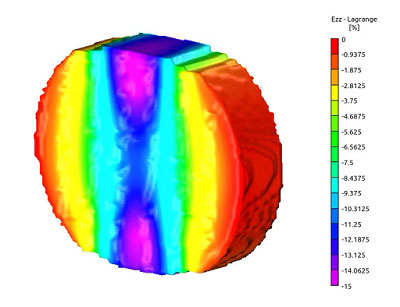

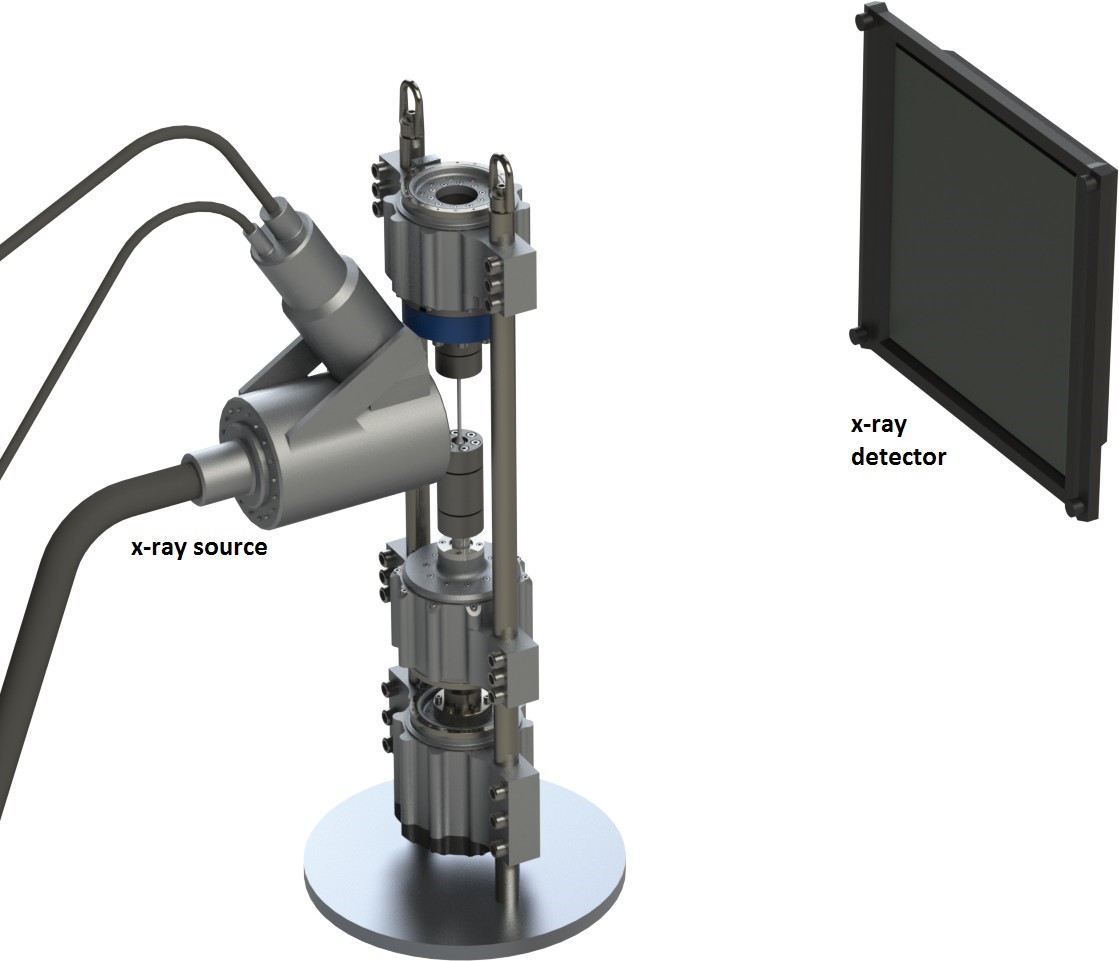

Psylotech的xTS是一种设计用于X射线断层成像系统内的原位加载机械测试系统。xTS在CT扫描过程中是载荷系旋转而非框架本体,从而解决了传统加载装置存在的支撑柱干扰X射线的问题。通过旋转载荷系还允许将探测器放置在尽可能靠近样品的位置,对射线能量有更高的利用率。

Psylotech’s xTS is mechanical testing system designed for use with x-ray tomography imaging systems. The xTS rotates the load train in the CT scanning process, thereby solving the problem of support columns interfering with x-rays. The rotating load train also allows the detector to be placed as close as possible to the specimen.

该系统是基于Psylotech的运动控制平台,是专门设计用来限制离面运动的系列仪器中的一款,着重于改善图像捕捉质量。例如,在光学显微镜下,离面运动的标准偏差已被证明小于1微米。控制离面运动对于X射线断层扫面描同样很重要,因为它的分辨率可以达到2微米或更小。

Built on Psylotech’s motion control platform, it is part of a line of instruments specifically designed to limit out of plane motion, thereby improving image capture. For example, under optical microscopes, standard deviation of out of plane motion has been shown to be less than one micron. Controlling out of plane motion is important for x-ray tomography, when resolution can be as fine as 2 microns.

Psylotech专利的加载框架设计通过:1/加载对称、2/高加工精度和3/直接驱动丝杠作动器控制平面外运动,通过精度为0.005mm的公差基准面与设计对称性相结合,有效控制额外的弯矩。关键的是,作动器实现了运动部件的绝对最少化,伺服电机的转子是螺母,丝杠随着螺母的转动而转动。最少化的运动部件可减少误差累积,保持精度。

Psylotech’s patented load frame design controls out of plane motion through 1/loading symmetry, 2/high machining accuracy, and 3/a direct drive roller screw actuator. Precision 0.0002” tolerance reference surfaces combine with design symmetry to prevent extraneous out of plane forces. Crucially, the actuator implements the absolute minimum of moving parts. The servomotor’s rotor is the nut and the screw translates as the nut rotates. Minimizing moving parts reduces tolerance stack- up, maintaining precision.

直接驱动滚柱丝杠还有另一个重要的优点,相较于采用齿轮箱或皮带传动装置的加载框架,没有引入额外的弯矩,而这些力会导致框架的扭曲变形,会使样品从初始加载平面偏离。 而Psylotech的xTS没有变速箱, 它通过直接驱动消除了这种扭曲力。

The direct drive roller screw has another substantial advantage. Alternative frames implement gear boxes or belt drive transmissions, introducing extraneous out of plane forces. These forces twist and contort the frame, moving samples away from the initial loading plane. Psylotech’s xTS has no gearbox. Its direct drive eliminates such twisting forces.

与其他系统相比,直接驱动伺服还具有相当的速度优势,因此每次断层扫描可以在更短的时间内完成。此外,样本旋转的测量直接来自用于伺服反馈的26位编码器。26位分辨率意味着xTS可以旋转0.0000054度。

The direct drive servo also enables substantial speed compared to other systems, so each tomography scan can be completed in less time. Moreover, specimen rotation is measured directly with the same 26-bit encoder used for servo feedback. The 26-bit resolution means the xTS can resolve 0.0000054 degrees in rotation.

除了可以施加轴向载荷,xTS还具有扭转试验能力。同样的,扭转伺服执行器通过零齿隙的谐波驱动,而不会产生额外的扭转力。这些伺服系统控制丝杠的旋转,丝杠按比例从属于螺母,以控制位移和角度位置。高刚性的结构和直接驱动载荷系减少了转角测量的误差。

In addition to axial loading, the xTS implements torsion capabilities. Again, the torsion servo actuator implements a zero backlash harmonic drive that does not cause extraneous twisting forces. These servos control the rotation of the screw, which is ratiometrically slaved to the nut to control displacement and angular position. The rigid, direct drive load train reduces error between measurement and angle at the grip.

最后,xTS还可以配置环境腔。该环境腔前后各有一个窗口,以允许X射线通过。为使内部体积最小化,可将该室旋转90度,以容纳轴向或梁弯曲样品。减小体积可提高效率、简化控制并提高温度均匀性。

Finally, the xTS can be configured with a temperature chamber. The chamber would have a window in front and back to allow x-ray pass through. To minimize internal volume, this chamber can be rotated 90 degrees in order to accommodate axial or beam bending samples. Minimizing volume improves efficiency, simplifies control and improves temperature uniformity.

总之,Psylotech的xTS通过对称性设计、精密的加工品质和直接驱动作动器的组合,独特地控制了样品在测试过程的离面运动。因为数字体相关的分辨率可以小到2微米,所以控制离面运动对于X射线断层成像非常重要。xTS还提供26位的角度分辨率并保有未来增加环境腔的扩展潜力。

In summary, Psylotech’s xTS uniquely controls out-of-plane motion though a combination of symmetry, precision machining and a direct drive actuator. Controlling out-of-plane motion is important for x-ray tomography, because digital volume correlation resolution can be as small as 2 microns. The xTS also offers 26-bit angular position resolution and future expansion potential with an environmental chamber.

Specifications

|

force capacity (kN) |

1.6 |

4.5 |

10 |

25 |

45 |

|

force resolution (mN) |

3 |

10 |

20 |

50 |

5000 |

|

stroke (mm)* |

40 |

24 |

25 |

25 |

100 |

|

max. speed (mm/s)** |

145 |

36 |

175 |

70 |

2 |

|

system height (mm)*** |

450 |

236 |

850 |

||

|

angular resolution |

26-bit (0.0000056°) |

||||

|

bearing runout (µm) |

2.5 |

4 |

8 |

||

|

nominal mass (kg) |

6 |

20 |

65 |

||

*minimum value, longer strokes available at expense of system height

**higher speeds available at expense of force capacity

***minimum value, system height easily increased

xTS在美国实验力学学会 SEM 2020年会上的介绍